Motor Technology

IPM Motor Features

Structure of the IPM (interior permanent magnet) motor

A conventional SPM (surface permanent magnet) motor has a structure in which a permanent magnet is attached to the rotor surface. It only uses magnetic torque from a magnet. On the other hand, the IPM motor uses reluctance through magnetic resistance in addition to magnetic torque by imbedding a permanent magnet in the rotor itself.

Example) SPM.IPM Motor Rotor Structure

IPM (Interior Permanent Magnet) Motor Features

: High torque and high efficiency

High torque and high output is achieved by using reluctance torque in addition to magnetic torque.

: Energy-saving operation

It consumes up to 30% less power compared to conventional SPM motors.

: High-speed rotation

It can respond to high-speed motor rotation by controlling the two types of torque using vector control.

: Safety

Since the permanent magnet is embedded, mechanical safety is improved as, unlike in a SPM, the magnet will not detach due to centrifugal force.

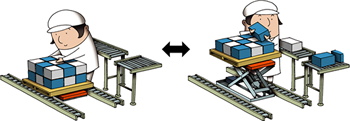

Example of GLP usage

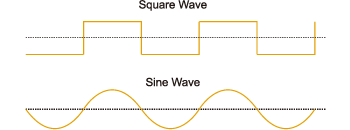

Vector Control Features

While a conventional system (120 degree conduction system) has the current impressed in the motor as a square wave, a vector control impresses voltage which turns into a sine wave towards the rotor's position (angle of the magnet), so it becomes possible to control the motor current.

This feature has the following advantages.

- Operation that is efficient and with low torque pulsation can be attained.

- By being able to control the motor current according to the angle of the magnet, smoother acceleration and accurate stop system can be achieved.

- It can instantly respond to speed changes during load fluctuations.

- Compared with conventional systems, the degree of speed regularity greatly improves when lifting or lowering, regardless of the load.